Manuel Serna and Hannah Power of Iberchem explain how the advancement of biodegradable testing capabilities, and novel biodegradable encapsulation technologies have empowered the development of new sustainable fragrance innovations

Biodegradability is undeniably one of the most valuable properties a raw material can possess to ensure the production of more sustainable products and to empower the movement towards a greener and cleaner world.

In recent years, there has been an increase in the level of consumer awareness and commitment regarding the sustainability of products and their environmental impact, with 49% of UK consumers stating they are willing to pay more for sustainability (Deloitte).

This growth of environmental awareness globally increases the pressure for brands to commit to sustainable solutions. Even 49% of UK adults are prepared to boycott companies who behave unethically and 72% are actively buying more environmentally friendly products (Mintel).

As a result, joining the movement to create eco-ethical, sustainable products leads to brands exploring innovative ways to reduce its impact on the planet and commit to sustainable solutions. One answer to this problem is biodegradable solutions.

The existing problem with all non-biodegradable and bio-accumulative products has been exacerbated in the last decade globally due to all industrial sectors. Consequently, governments and several organisations have begun to focus their efforts and legislation on promoting a transition towards a more sustainable world.

The European Chemicals Agency (ECHA) proposing restrictions on microplastics in products placed on the EU/EEA market is a clear example of this. The proposal is expected to prevent the release of 500,000 tonnes of microplastics over 20 years by banning the use of microplastics in cosmetics, detergents, fertilisers to avoid or reduce their release to the environment.

Fragrance house Iberchem, as part of Croda International, understands that innovating biodegradable consumer products, thinking not only about the improvement of industrial processes, but also, and above all, about the environment and the responsible use of the planet, ensures biodegradability is one of the best tools for creating more sustainable products and reducing the impact of bioaccumulative substances.

From introducing Vernova, Iberchem’s range of biodegradable olfactive solutions, to launching IB-BI, Iberchem’s in-house biodegradability testing laboratory, Iberchem is committed to innovating creative products. Sustainable and biodegradable solutions are no longer an added benefit for commercial products, they now have become fundamental when trading products in the fragrance market.

Biodegradability in the world of fragrances

Biodegradability is a characteristic that certain compounds need to be metabolised by microorganisms, such as bacteria and fungi, and also to serve as a substrate in oxidation processes releasing CO2 and water (Figure 1). In addition, it is a process that allows microorganisms to obtain the energy necessary for life, or for synthesis processes in which much more complex products are made.

Figure 1: Biodegradability equation

In this sense, biodegradability is a determining parameter for the environmental performance of chemical products intended for fragrances and, therefore, makes it a desired property for products that are released in large quantities into the natural environment, such as fragrances, microcapsule formulations, raw materials, or bases, etc.

The legislation that includes the foundations for carrying out biodegradability tests has been reviewed by the Organization for Economic Cooperation and Development (OECD). All the tests to measure biodegradability and toxicity are listed here and each one is based on the measurement of different parameters, in the case of the fragrance industry and Iberchem, the OECD 301F standard has been followed.

In addition, according to the IFRA criteria, the biodegradability of fragrances is determined by the biodegradability values of each raw material that makes up the fragrance and its percentage in terms of composition.

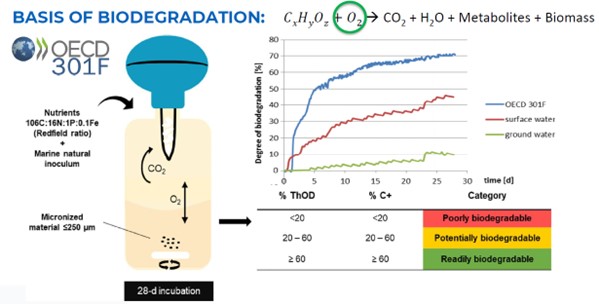

As shown in Figure 2, OECD 301F is a solution aerobic biodegradation test that determines the biodegradability of a material by measuring oxygen consumption over 28 days using the Biological Oxygen Demand (BOD) and Theoretical Oxygen Demand (ThOD) parameters. It is a method that allows the measurement of insoluble and volatile materials, something fundamental for the analysis of fragrances.

Figure 2: Process of the OECD301F standard

The basics of the standard are simple, since they are based on oxygen consumption. If there is oxygen consumption, it means that the raw material under study is digested by the microbial inoculum. So, the BOD device represented in blue in Figure 2. collects the values of the internal pressure change. These values are sent to a software that, combined with the ThOD, provides the biodegradability values after 28 days. Finally, the biodegradability classification is as follows:

- If these values exceed 60%, it is determined as "readily biodegradable".

- If the values are greater than 20%, but less than 60%, the element is considered "potentially biodegradable" and requires rethinking the test.

- If the values are less than 20%, the non-biodegradable criterion is established.

The development of reliable biodegradability testing methodologies in accordance with OECD within the fragrance industry ensures a strong step forward for sustainable fragrance innovation.

A key instance is the IB-BI biodegradability testing laboratory which increases brand’s agility to meet the global need for environmentally friendly products by ensuring a faster response to consumer demands for biodegradable olfactive solutions.

As a result, in-house testing across the industry to effectively determine the biodegradability of fragrances, facilitates great potential with fast and efficient scalability.

Biodegradability in microcapsules

The encapsulation of fragrances has numerous benefits and is important in contributing to the controlled, gradual release of aroma compounds. Encapsulation therefore prolongs fragrance exposure making it a beneficial technique to create effective, high performance consumer expectations.

Although it is important to consider that each new chemically synthesised products such as capsules have specific properties such as molecular structure, molecular weight, polarity, etc. All these physicochemical properties of the new molecules pose a great challenge for microbial biodegradation since their digestive machinery is not designed for the degradation of new compounds. Everything depends on the structural similarity with other natural molecules and the ability of a microorganism to assimilate this new molecule.

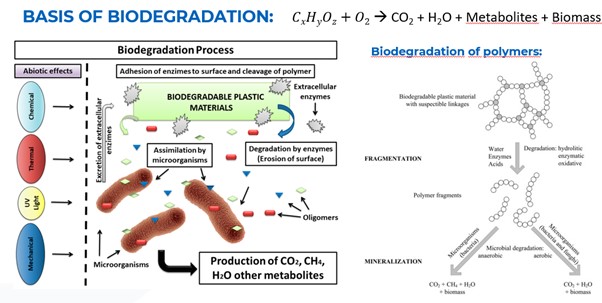

The problem of polymers and microplastics derived from formulations and the encapsulation processes is similar to that of new petrochemical synthesis molecules (Figure 3). They pose an enormous digestion challenge for microorganisms due to their macromolecular or polymeric structure.

Also, as the origin is usually petrochemical, there are metabolic deficiencies when degrading different monomers or components of the wall, contributing to toxicity.

The main difficulty is the assimilation of large macromolecules, which is practically unfeasible for microorganisms and, on the other hand, involves environmental bioaccumulation problems, causing the chain of damage described above. Another problem is the lack of enzymatic digestion capacity, since current microorganisms do not have genomics to produce the appropriate enzymes to degrade these materials, so they often depend on molecular similarity to activate the cascade of metabolic and enzymatic reactions.

As a result, the process of environmental bioaccumulation begins - the clear example being plastics. Plastic accumulation is creating serious problems and weakens the defences of the environment, both in flora and fauna, since in the long term, the health of wild animals and those that are raised for consumption are also affected.

Figure 3: The biodegradation stages and the digestion problem of microplastics and polymeric structures

Conclusion

Biodegradability is an effective tool for constructing sustainable olfactive solutions and reducing emissions into the environment from persistent or bioaccumulative substances.

The advancement of biodegradable testing capabilities, and novel biodegradable encapsulation technologies empower the development of new sustainable fragrance innovations. As a result, improvement can be progressively made to help solve various environmental problems contributed to by the fragrance and personal care industries.